Collection: View Our Entire Catalog

Explore our complete catalog. At RetroFixes, we aim to assist you in expanding your collection. Whether you choose to buy a refurbished gaming console or seek the components necessary for a DIY refurb, we have you covered. From retro computer equipment to DIY music synth kits, we've got everything you need!

-

Custom N64 RGB Upgraded Console with Translucent Smoke Shell

5.0 / 5.0

(1) 1 total reviews

Regular price $ 325.00 USDRegular priceUnit price / per -

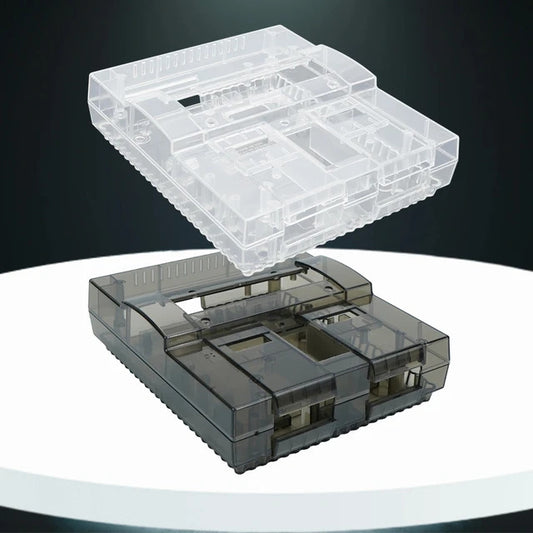

Custom SNES RGB Translucent Smoke Black Console

5.0 / 5.0

(2) 2 total reviews

Regular price $ 300.00 USDRegular priceUnit price / per -

Sold out

Sold outSuper Nintendo SNES Jr RGB Console

5.0 / 5.0

(4) 4 total reviews

Regular price $ 300.00 USDRegular priceUnit price / per -

Sold out

Sold outNES & Famicom RGB Upgrade Service.

5.0 / 5.0

(1) 1 total reviews

Regular price From $ 175.00 USDRegular priceUnit price / per -

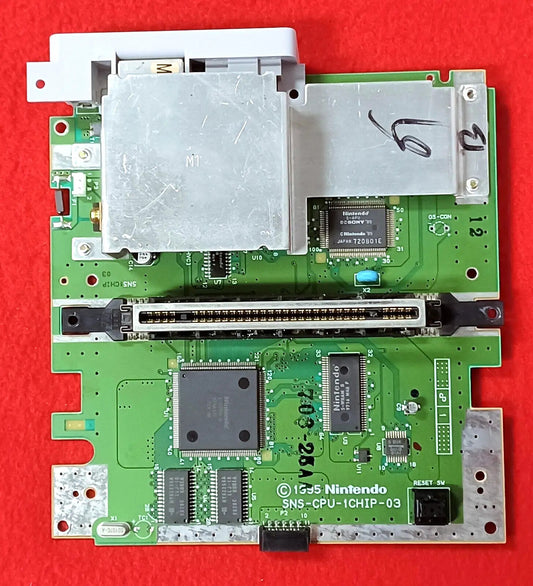

Super Nintendo SNES 1 Chip - 03 Motherboard Replacement

Regular price $ 140.00 USDRegular priceUnit price / per -

N64 RGB Upgrade Service

5.0 / 5.0

(4) 4 total reviews

Regular price From $ 120.00 USDRegular priceUnit price / per -

Nintendo NES Toploader Composite Upgrade Service

4.58 / 5.0

(45) 45 total reviews

Regular price $ 120.00 USDRegular priceUnit price / per -

Deluxe SNES Jr RGB Video Upgrade Service

5.0 / 5.0

(5) 5 total reviews

Regular price $ 120.00 USDRegular priceUnit price / per -

SNES Upgrade RGB Bypass + Vertical Line + Ghosting Fix Service

5.0 / 5.0

(2) 2 total reviews

Regular price From $ 100.00 USDRegular priceUnit price / per -

Super Nintendo SNES Power Port Repair

5.0 / 5.0

(1) 1 total reviews

Regular price From $ 75.00 USDRegular priceUnit price / per -

SNES Console Shell Replacement Service

Regular price $ 70.00 USDRegular priceUnit price / per -

Sold out

Sold outPlastic Cleaning Kit

Regular price $ 50.00 USDRegular priceUnit price / per -

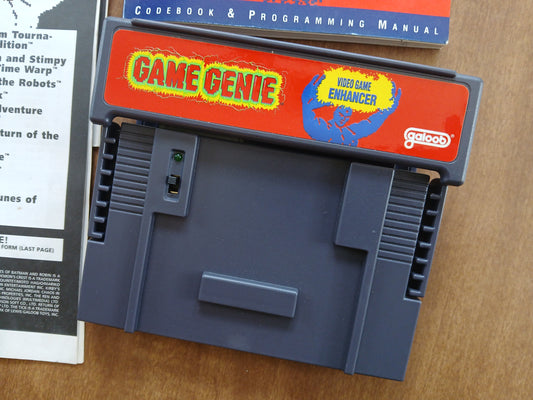

SNES Game Genie complete with original paperwork

Regular price $ 50.00 USDRegular priceUnit price / per -

Console Refurbishment Service

Regular price From $ 49.00 USDRegular priceUnit price / per -

Vintage Macintosh Mouse & Keyboard Repairs. 512k, 1mb & more.

Regular price $ 49.00 USDRegular priceUnit price / per -

ViewMaster Focusing Model D Restoration & Repair Service

Regular price From $ 49.00 USDRegular priceUnit price / per -

SNES SHVC Sound Module Board

Regular price $ 45.00 USDRegular priceUnit price / per -

Original Nintendo Famicom Console - Bargain Sale

5.0 / 5.0

(2) 2 total reviews

Regular price $ 45.00 USDRegular priceUnit price / per -

Sold out

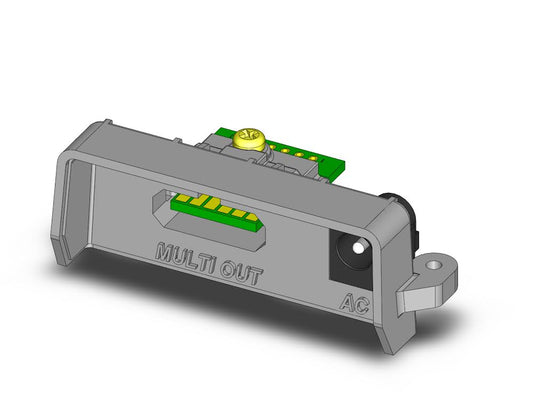

Sold outNES Toploader Custom Multiout Port

5.0 / 5.0

(1) 1 total reviews

Regular price $ 39.00 USDRegular priceUnit price / per -

Nintendo Famicom Disk System - RAM Adapter

Regular price $ 39.00 USDRegular priceUnit price / per -

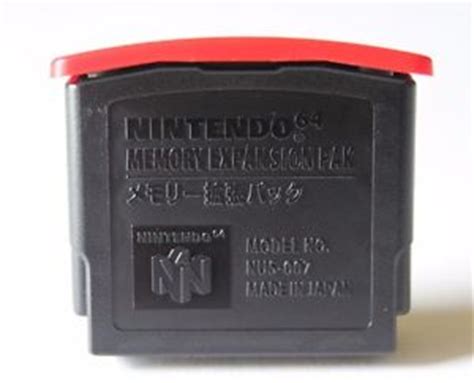

Nintendo 64 Expansion Pack NUS-007 OEM N64 Official

Regular price $ 38.95 USDRegular priceUnit price / per -

SNES SPDIF Digital Audio Board

5.0 / 5.0

(1) 1 total reviews

Regular price $ 35.00 USDRegular priceUnit price / per -

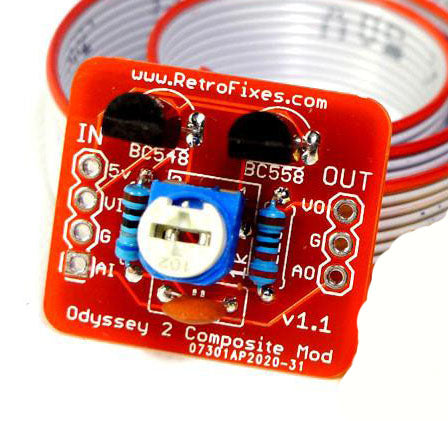

Magnavox Odyssey 2 Composite Video Board

5.0 / 5.0

(2) 2 total reviews

Regular price $ 35.00 USDRegular priceUnit price / per -

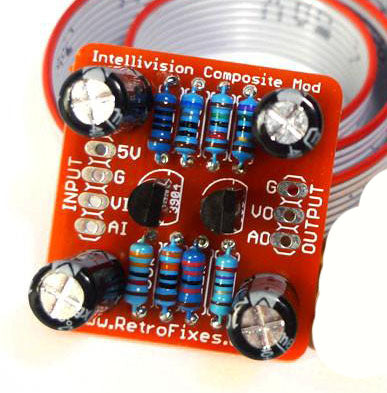

Intellivision Composite Video Board

5.0 / 5.0

(3) 3 total reviews

Regular price $ 35.00 USDRegular priceUnit price / per -

NES-101 Composite Video Board

5.0 / 5.0

(3) 3 total reviews

Regular price $ 35.00 USDRegular priceUnit price / per -

NES Toploader Custom RCA Composite Port

5.0 / 5.0

(1) 1 total reviews

Regular price From $ 35.00 USDRegular priceUnit price / per -

SNES RGB Video Board

4.82 / 5.0

(50) 50 total reviews

Regular price $ 35.00 USDRegular priceUnit price / per -

Colecovision Composite Video Board

4.89 / 5.0

(37) 37 total reviews

Regular price $ 35.00 USDRegular priceUnit price / per -

Commodore C64 / 64C JailBar Eliminator LumaFix64 Kit

Regular price $ 29.95 USDRegular priceUnit price / per -

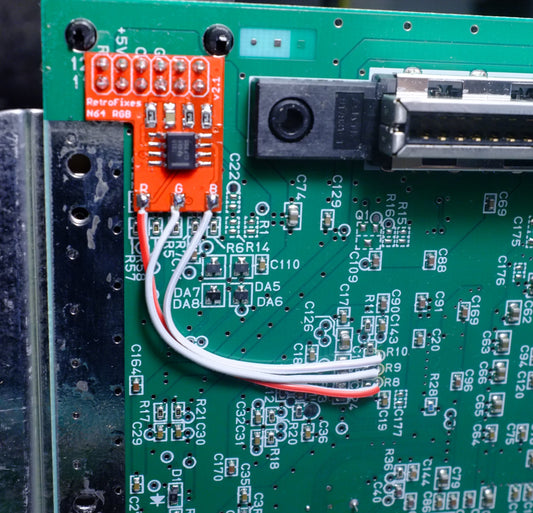

N64 RGB Video Board

4.86 / 5.0

(14) 14 total reviews

Regular price $ 29.00 USDRegular priceUnit price / per -

Original Nintendo Multiout Port GC, N64 or SNES versions

Regular price $ 29.00 USDRegular priceUnit price / per -

Sold out

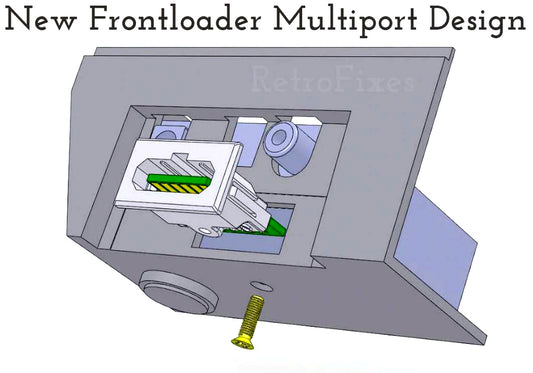

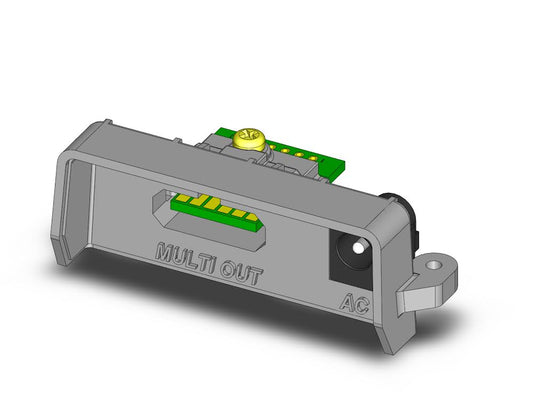

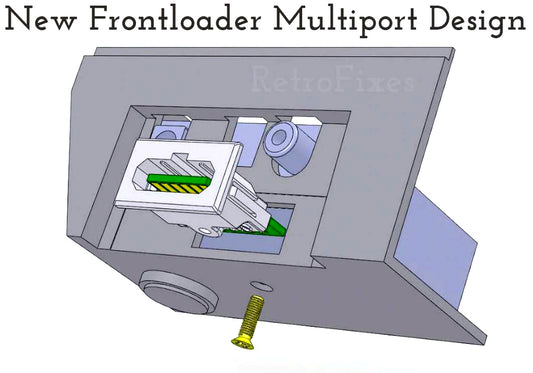

Sold outNES Frontloader Multiout Port

Regular price $ 29.00 USDRegular priceUnit price / per -

Sold out

Sold outNES RetroN 1 AV Gaming Console

Regular price $ 29.00 USDRegular priceUnit price / per -

Famicom to NES Game Adapter Expansion Audio Enabled 60 to 72 Pin Convertor

5.0 / 5.0

(1) 1 total reviews

Regular price $ 28.00 USDRegular priceUnit price / per -

LM1881 Sync Stripper-in-SCART Board

5.0 / 5.0

(1) 1 total reviews

Regular price $ 26.00 USDRegular priceUnit price / per -

Sold out

Sold outRetro Computer Brick Set 228pcs

Regular price $ 25.00 USDRegular priceUnit price / per